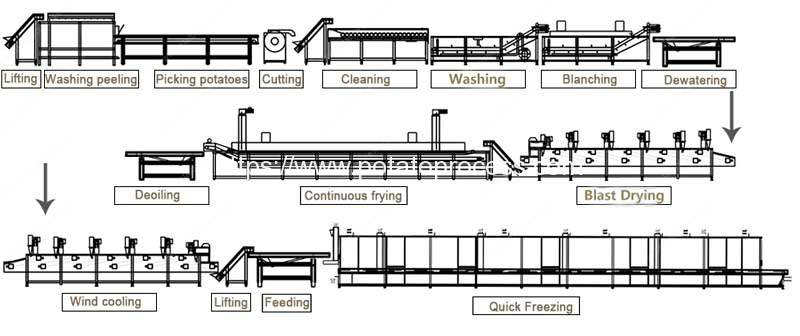

Frozen French Fries Production Line is used to produce semi-finished french fries which can be sold to customers. When the customer gets the french fries can fry again and get their own flavor. Now, Frozen french fries production line is very popular on market for Mac Donald, KFC and supermarkets frozen french fries. A frozen French fries production line typically consists of a series of machines and processes that are used to transform raw potatoes into frozen French fries that are ready for consumption. The following is a brief introduction to the different stages of a typical frozen French fries production line:

- Potato Washing and Peeling Machine: The first stage of the process involves the cleaning and peeling of the raw potatoes. This is typically done using specialized machines that remove any dirt or debris and peel the potatoes using high-pressure water or mechanical abrasion.

- Potato French Fries Cutting Machine: Once the potatoes are cleaned and peeled, they are fed into a cutting machine that slices them into thin, uniform strips. This can be done using a variety of cutting methods, including blades, water jets, or lasers.

- Potato Stick Impurity Sorting Cleaning Machine: The cut potato stick will have some very small sizes mixed. in order to get high-quality final frozen french fries, we need to remove these very small or granule sticks.

- Potato Stick Washing Machine: The cut potato stick will fall in the water machine for water washing, so we can get clean potato sticks to avoid dirty.

- French Fries Blanching Machine (potato stick blanching machine): After the potatoes have been cut, they are blanched in hot water or steam for a short period of time. This helps to partially cook the potatoes and remove excess starch, which can affect the texture and color of the final product.

- Potato Stick Dryer Machine: after french fries get out of the blanching machine, there will have much water on the potato stick surface, in order to save energy and avoid too much water in the frying machine. we use this machine to remove the surface water. This step realizes by a vibrating water removing machine or air blow water removing machine.

- French Fries Fryer Machine: frying machine will fry the potato stick to get semi-finished french fries. which makes the french frieses keep longer time and easy to fry when customers get them.

- Half Fried French Fries Drying Machine: Once the potatoes have been fried, many oils will be on the french fries, we need to remove the extra oil to keep the french fries clean and healthy. This step realizes by a vibrating oil-removing machine or air blow oil removing machine.

- French Fries Instant Freezing Machine: The dried French fries are then frozen using a quick-freezing process, which helps to preserve their quality and texture. This is typically done using a blast freezer or a fluidized bed freezer, which exposes the French fries to extremely cold temperatures for a short period of time.

- Frozen French Fries Packaging Line: Finally, the frozen French fries are packaged in bags or boxes and prepared for distribution to retailers or food service providers.

Frozen French fries production line is a complex system that requires specialized equipment and skilled operators to produce high-quality frozen French fries that meet consumer demand.

Frozen French Fries Production Line Processing Flow

Automatic Frozen French Fries Production Line Detail Equipment List Introduction

1. Potato Feeding Elevator

Potato Feeding elevator is used to feed potatoes to the following potato washing peeling machine. It can realize automatic feeding and save labor cost.

2. Screw Feeding Type Potato Washing and Peeling Machine

Screw Feeding Type Potato Washing Peeling Machine is used washing and peeling the potato. It adopts a screw feeding design which makes potatoes automatically move forwarder in the peeling machine. This screw-type potato washing peeling machine also be used to peel other root vegetables and fruits, such as potatoes, carrots, sweet potatoes, ginger, radish, taro, kiwi fruit, root-stock materials, Areca Seed, Betel nuts, etc. Machine design is reasonable and easy to keep clean.

3. Peeled Potato Selecting Conveyor

After potato peeling, the unqualified potato can be removed when it moving on this conveyor. This conveyor adopts food-grade PVC material. The frame adopts SUS304 stainless steel made and the conveyor speed is adjustable

4. Potato Chips Cutting Machine

Potato Stick & Chips Cutting Machine is used for cutting potato to stick or chips. It can cut potato, sweet potato, carrot to stick shape or flake shape. After cutting, the surface of the potato or carrot is smooth. The processing material is suitable for steam processing, boiling process, fry processing.

Specification of Potato Stick Cuting Machine

- Model: RM-PC800

- Dimension:660*560*900mm

- Weight:125KG

- Output:600-800KG/H

- Voltage:380V/220V (can be customized)

- Power:1.5HP

- Material: Stainless Steel

5. Elevator

The elevator is used to feed potatoes to the following potato stick brush cleaning machine. It can realize automatic feeding and save labor cost.

6. Potato Stick Water Washing Machine

Air Bubble Type Potato Washing Machine washes dirt attached on the surface of potato by air bubble washing, which can be used for many Vegetable & Fruit washing. It imitates human washing motion and avoids collision or friction damages caused by human washing. It is suitable for washing fresh vegetables, preserved vegetables, fungus, marine products, etc.

7. Potato Stick Impurity Removing Machine

Potato stick impurity removing machine is used to remove the certain size potato sticks during the moving between brush and it can remove impurity on the cutted potato chips or potato sticks surface. We also equipped water spray device to clean it. Fruits and vegetables roll with working brush by a different direction, and the soft brush is able to reach into their skin folds to clean sundries; the high-pressure spraying system is working simultaneously to wash the products. The cleaning water is collected in the collecting tank for recycling use.

8. French Fries Hot Water Blanching Machine

Full Automatic Hot Water Blanching Machine is widely used for blanching and sterilizing vegetables, fruits, seafood products before quick freezing and dehydrating, especially suitable for easily damageable or color protection requirement product and products in strips or bar-shaped. It is necessary equipment during food processing industry.

We provide different heating source blanching machine, like electric heating hot water blanching machine, natural gas-fired hot water blanching and diesel oil fired hot water blanching machine and coal-fired hot water blanching machine.

9. French Fries Vibrate Water Removing Machine

Automatic Frying French Fries Vibrate Oil Removing Machine can be used to remove oil on frying french fries surface and the vibrate strength is adjustable. It can also be used for water removing on the vegetable or fruit surface. Vibrate Oil Removing Machine is an ideal machine to a vegetable processing line to realize full automatic working flow.

10. French Fries Air Blow Water Removing Machine

Automatic Air Blower Dryer Machine is used to remove the water or oil on the product. Automatic Air Blow Deoiling Machine adopts mesh belt feeding which allows oil or waterfall on the collection device. We make a special design feeding mesh belt, which makes the product can turnover when moving the mesh belt, so the whole product water or oil can be removed. High Pressure Blower will remove the water and oil very fast. Automatic French Fries Deoiling Machine adopts SUS304 stainless steel material made and the speed is adjustable. The blower height is adjustable.

11. French Fries Elevator

12. Automatic French Fries Frying Machine

Automatic Natural Gas Heating Oil-Water Separator Frying Machine adopt natural gas fuel as heating source, which make sure the operation cost is low than electricity heating. Adopting oil-water separator technology, the scraps that produced can be fall into water automatically while frying, so it will not waste oil. This kind of fryer can save much more oil by 50%–60% than normal fryer. It is suitable for all kinds of fried foods and the oil temperaturecan be adjusted from 0–300 °C ( 572 degrees F ). While frying, it will not appear carbonization phenomenon . The oil can be recycling reused and No need to change oil everyday.

13. Oil Filter Machine for French Fries Fryer

During the working, the oil in the dryer machine will get into the oil filter device by the circulation pump and the impurity in the oil will be removed from the oil.

14. French Fries Vibrate Oil Removing Machine

Automatic Frying French Fries Vibrate Oil Removing Machine can be used to remove oil on frying french fries surface and the vibrate strength is adjustable. It can also be used for water removing on the vegetable or fruit surface. Vibrate Oil Removing Machine is an ideal machine to a vegetable processing line to realize full automatic working flow.

15. Air Blower French Fries Oil Removing Machine

Automatic Air Blower Deoiling Machine is used to remove the water or oil on the product. Automatic Air Blow Deoiling Machine adopts mesh belt feeding which allows oil or waterfall on the collection device. We make a special design feeding mesh belt, which makes the product can turnover when moving the mesh belt, so the whole product water or oil can be removed. High Pressure Blower will remove the water and oil very fast. Automatic French Fries Deoiling Machine adopts SUS304 stainless steel material made and the speed is adjustable. The blower height is adjustable.

16. Stainless Steel Mesh Belt Elevator

17. Frozen French Fries Instant Freezer Machine

Tunnel quick-freezing machine (also called as net belt freezer machine) adopt blast freezer principle, It is widely used as an all-in-one freezer for frozen french fries, dumplings, glutinous rice balls, steamed bag, aquatic meat product, poultry products and fruits, vegetable for processing.

Automatic Tunnel Freezer Machine (net belt tunnel quick freezer) uses a stainless steel net belt as the conveyor. According to different varieties, the products to be frozen can be put in the tray or directly on the conveying belt, and be rapidly frozen by the wind blowing from the top to the bottom or by the side wind.

18. Frozen French Fries Packing Machine

Full Automatic French Fries and Potato Chips Packing Plant is suitable for automatic packaging particle materials like potato chips, french fries, garlic clove, shrimp, sweets, garlic, chocolate, biscuits, peanuts, nuts, rice, grain, seeds, pistachio, coffee beans, lima beans, tea, jelly, frozen food, chicken essence, sugar and salt . We provide different designs according to customer requirements. This full-automatic weighting packing plant includes a vibrating feeding device, Z shape elevator, multi-head weigher, support platform, automatic bag forming packing machine and take away conveyor.

FAQ for Frozen French Fries Production Line

What types of potatoes are used in frozen french fries production?

The most commonly used potato varieties for frozen French fries production are Russet Burbank and Shepody, although other varieties such as Innovator and Markies are also used. Potatoes with a high starch content are preferred for making French fries, as they result in a crispier texture.

What are the different types of frozen french fries production lines?

There are several types of frozen French fries production lines available on the market, including semi-automatic lines, fully automatic lines, and modular lines. Semi-automatic lines require some manual labor, while fully automatic lines are fully automated and require less human intervention. Modular lines allow for customization and flexibility in the production process.

What is the capacity of a frozen French fries production line?

The capacity of a frozen French fries production line can vary depending on the size and type of the equipment used. A small production line may have a capacity of 100-200 kg per hour, while larger lines can produce up to 500-2000kg or more per hour.

What are the different types of fryers used in frozen French fries production lines?

There are two main types of fryers used in frozen French fries production: batch fryers and continuous fryers. Batch fryers are used for smaller production runs and cook fries in batches, while continuous fryers are used for larger production runs and cook fries in a continuous flow.

What is the ideal frying temperature for frying French fries?

The ideal temperature for frying French fries is between 325-375°F (163-191°C). Frying at higher temperatures can result in overcooked or burnt fries, while frying at lower temperatures can result in soggy or undercooked fries.

What are the requirements for packaging frozen French fries?

Frozen French fries are typically packaged in plastic bags or boxes. The packaging must be able to withstand the freezing temperatures and protect the fries from freezer burn. The packaging must also meet food safety regulations and be labeled with information such as the product name, weight, ingredients, and nutritional information.

How to Store frozen French fries before distribution or selling?

Frozen French fries are typically stored in a freezer at temperatures between -18°C and -23°C (-0.4°F and -9.4°F). Proper storage is important to maintain the quality of the product and prevent freezer burn. The shelf life of frozen French fries can vary depending on factors such as the storage temperature, packaging, and production methods. Generally, frozen French fries have a shelf life of 6-12 months when stored at 0°F (-18°C) or lower. Frozen French fries are typically transported and stored in refrigerated or frozen conditions to maintain their quality and prevent spoilage. They are often shipped in temperature-controlled trucks or containers and stored in freezers until they are ready to be used.

Whate site is suitable for build frozen French fries production lines factory?

Frozen French fries production lines can have an impact on the environment due to the large amounts of water and energy required for the production process. Efforts to reduce water and energy usage, as well as proper waste management and recycling, can help minimize the environmental impact.

What are the common quality problem in frozen French fries production line?

frozen French fries production line product problem include discoloration, uneven size and shape, excessive oil or moisture, and off-flavors. These defects can be caused by various factors, including potato quality, processing conditions, and storage conditions. In order to avoid that, we need to monitor the potato quality, controlling the blanching and frying time and temperature, ensuring proper cooling and freezing, and conducting regular product testing to ensure consistent quality.

What are the potential challenges start frozen French fries manufacture business??

Some of the potential challenges of using a frozen French fries production line include the initial cost of purchasing the equipment, the need for skilled operators to run and maintain the machinery, the need for consistent quality control to ensure product consistency, and the need for proper maintenance and cleaning of the equipment to prevent contamination or breakdowns.

How to Purchase Frozen French Fries Production Line

Choose reliable frozen french fries machine manufacture with many year experience. so they can help to solve any problem during the production. Romiter Machinery have 20 year potato processing machine experience, we can help to solve any problem for frozen french fries business. Welcome to Contact us

Working Video of 1000kgh Frozen French Fries Production Line

Company Profile

Adhering to the principle of managing scientifically and honesty and credit,our factory has passed ISO9001-2000 quality system certification. Now, Our factory can provide potato dry cleaning machine, automatic potato washing peeling machine, potato peeling machine, french fries sticks cutting machine, potato grader, potato cleaning and sorting machine, potato chips production line, french fries production line, frozen french fries production line, wave shape french fries production line, potato starch production line, potato mesh bag packing machine, potato dosing packing machine.

Our potato processing products have passed with CE,ISO and SGS Certificates and has been widely sold all over the world.